Jiangsu Haijian Co., Ltd is a professional China Separated vessel Manufacturers and Separated vessel Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

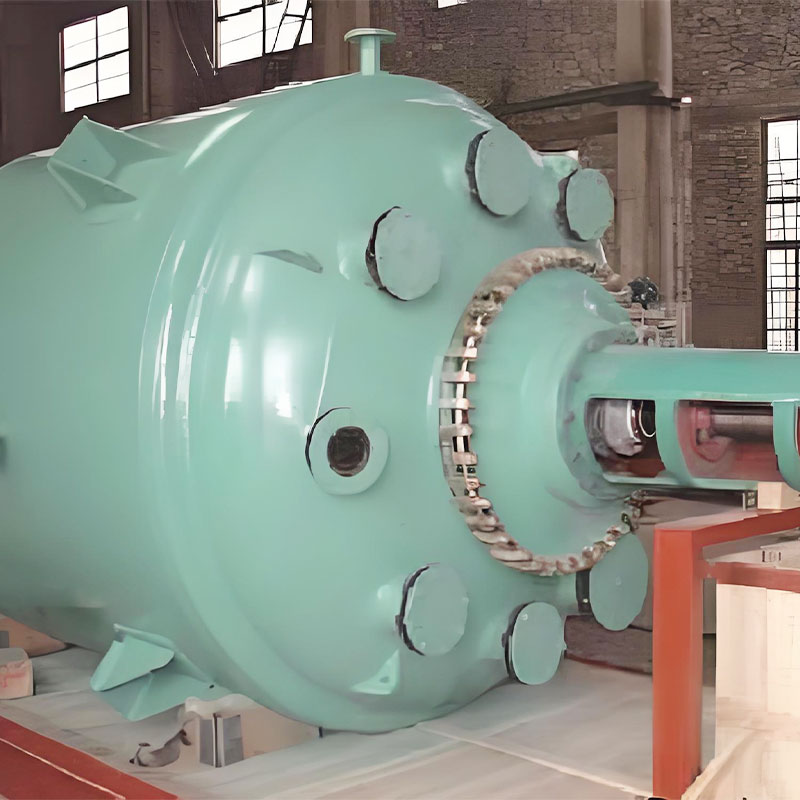

Separation vessels are devices used to efficiently separate different components (such as liquid-liquid, liquid-gas, and liquid-solid) in mixed materials. They are widely used in industries such as petrochemicals, pharmaceuticals, food processing, and environmental water treatment. Separation vessels are primarily used to balance liquid pressure and buffer media, as well as purify and separate gases. These vessels, such as separators, filters, copper scrubbers, drying towers, strippers, steam cylinders, and degassing units, are suitable for industries such as water treatment, food processing, and pipeline filtration. Jiangsu Haijian Co., Ltd. is a professional manufacturer and company of separation vessels. We provide specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgical applications. Their main functions include:

Media separation: such as oil-water separation, gas-liquid separation, and solid-liquid sedimentation.

Purification: Removing impurities to improve product purity.

Process optimization: Ensuring the stability and efficiency of subsequent processes.

Working Principle:

Separation vessels separate substances based on their physical properties (such as density, particle size, and solubility). Common methods include:

Gravity sedimentation: Utilizes density differences to cause the heavy phase to sink and the light phase to float (e.g., oil-water separators).

Centrifugal separation: Utilizes centrifugal force generated by high-speed rotation to accelerate separation (e.g., centrifuges).

Filtration/adsorption: Filters, membranes, or adsorbent materials are used to trap solid particles or specific components (e.g., activated carbon filters).

Swirl separation: Tangential feed creates a swirling flow to separate components of different densities (e.g., cyclones).

Advantages and Features:

High-efficiency separation: Designed for diverse operating conditions, offering high separation accuracy and processing capacity.

Stable structure: Utilizes corrosion-resistant and high-pressure-resistant materials (e.g., stainless steel, carbon steel lined with plastic), adaptable to harsh environments.

Automated control: Liquid level sensors and pressure gauges can be integrated for intelligent monitoring and automatic discharge.

Energy saving and environmental protection: Reduces waste emissions, increases resource recovery, and meets environmental requirements.

Maintenance:

Regular Inspections: Clean internal deposits and inspect seals and linings for corrosion.

Instrument Calibration: Ensure the accuracy and reliability of monitoring devices such as pressure gauges and level gauges.

Preventative Measures: Add backwash or chemical cleaning functions for scaling media.

Safety Measures: Regularly inspect explosion-proof devices (such as separation vessels for flammable and explosive media).

English

English  русский

русский  Español

Español