Jiangsu Haijian Co., Ltd is a professional China Reaction vessel Manufacturers and Reaction vessel Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

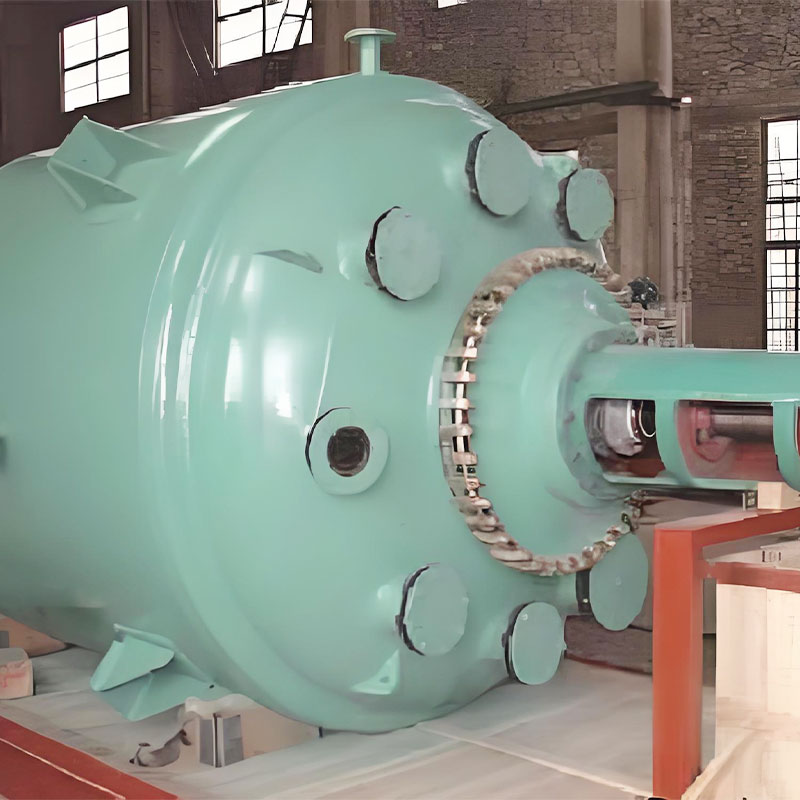

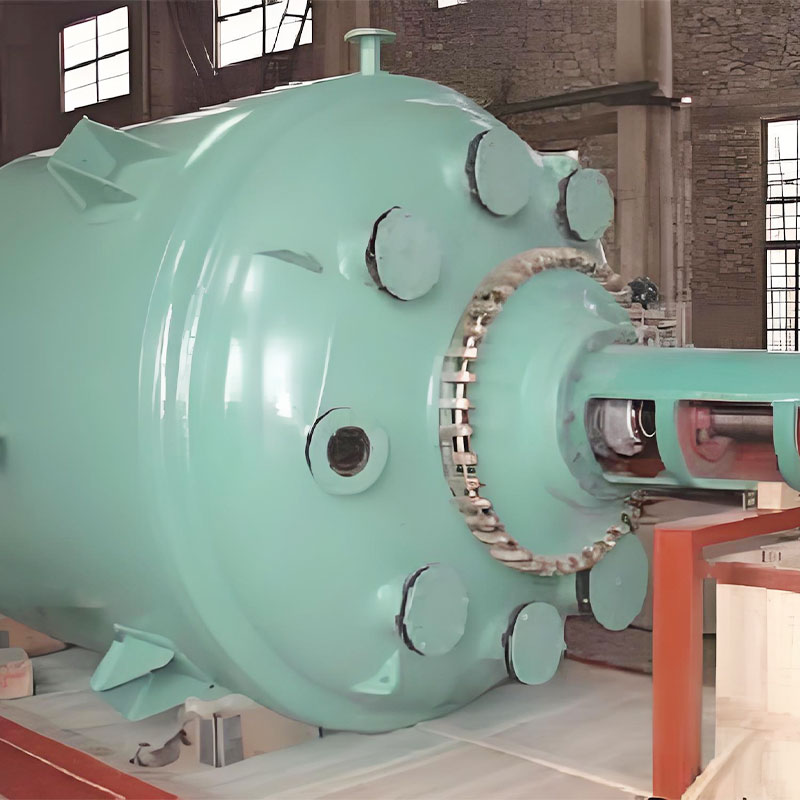

Reaction vessels are pressurized equipment used to carry out physical or chemical reactions in a medium. They are widely used in industries such as chemical, pharmaceutical, petroleum, fertilizer, and metallurgy. Reactors promote chemical reactions by optimizing the reaction environment. Reactors typically consist of a stirring system, sealing devices, heating/cooling modules, and pressure and temperature sensors. Through the combined effects of structural design and parameter control, they confine chemical reactions within specific physical boundaries, achieving substance transformation. Jiangsu Haijian Co., Ltd. is a professional reactor manufacturer and company, providing specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgical applications. The main functions of reaction vessels include:

Chemical reactions: Processes such as polymerization, catalysis, synthesis, and decomposition.

Physical reactions: Processes such as dissolution, crystallization, mixing, and heating/cooling.

Process control: Providing stable temperature, pressure, and stirring conditions to ensure efficient reaction progress.

Operating Principle:

Reaction vessels promote the desired reaction by controlling parameters such as temperature, pressure, and stirring speed. Common types include:

Stirred reactors: Mechanically agitate materials to uniformly mix, improving reaction efficiency.

High-pressure reactors: Conduct reactions such as hydrogenation and polymerization under high pressure.

Tubular reactors: Perform continuous flow reactions, suitable for large-scale production.

Fixed-bed/fluidized-bed reactors: Used for gas-solid catalytic reactions (such as petroleum cracking).

Product Advantages and Features:

High-pressure and corrosion-resistant: Made of stainless steel, titanium alloy, or glass-lined materials, they are suitable for harsh environments such as strong acids and bases.

Precise temperature and pressure control: Equipped with heating/cooling jackets, pressure sensors, and automated control systems.

Efficient stirring: Optimized stirring structures (such as paddle, anchor, and turbine) ensure reaction uniformity.

Safety and reliability: Complies with ASME, GB/T, and other standards, equipped with protective devices such as safety valves and bursting discs.

Maintenance Tips:

Regular Inspection: Check for internal wall corrosion, weld integrity, and sealing performance.

Cleaning and Maintenance: Thoroughly clean after reactions to prevent residue from affecting the next batch.

Instrument Maintenance: Calibrate temperature and pressure sensors to ensure data accuracy.

Safety Protection: Regularly replace wearing parts (such as seals) and test the opening and closing pressures of safety valves.

English

English  русский

русский  Español

Español