Jiangsu Haijian Co., Ltd is a professional China Storage vessel Manufacturers and Storage vessel Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

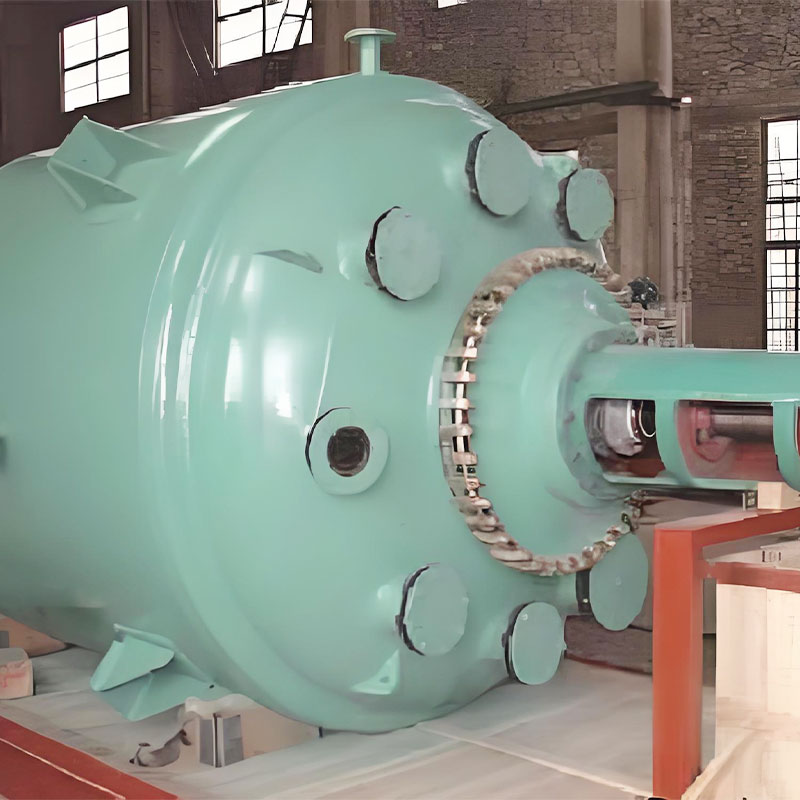

Storage vessels, essential infrastructure in industrial production, are primarily used to safely store and contain various gases, liquids, and liquefied gases. They are used in industries such as building materials and coatings, petroleum, chemicals, metallurgy, machinery, light industry, daily chemicals, and pharmaceuticals. Jiangsu Haijian Co., Ltd. is a professional storage tank manufacturer and company. We provide specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgy applications, widely used in industrial raw material storage, biological sample preservation, and other fields.

Application Areas

1. Traditional Industrial Applications

Building Materials and Coatings Industry: Storage of raw materials such as resins, solvents, and additives

Petrochemical Industry: Storage of crude oil, refined oil, and various chemical products

Metallurgical Machinery Industry: Storage of industrial oils, coolants, and metalworking fluids

2. Emerging Technology Applications

Biomedical Industry: Cryogenic storage of high-purity biological samples, vaccines, and reagents

New Energy Industry: Storage of new energy media such as liquid hydrogen and liquid oxygen

Environmental Engineering: Key components in environmental systems such as wastewater treatment and exhaust gas recovery

Core Design Concepts

1. Functional Design

Scientific Capacity Planning: From small containers of a few liters to massive storage tanks of tens of thousands of cubic meters

Specialized Structure: Designed pressure balancing and temperature control systems for different media

Convenient Interface: User-friendly inlets and outlets, monitoring instruments, and control systems

2. Safety Assurance

Multiple Protection Systems: Explosion-proof, leak-proof, and anti-static safety devices

Emergency Response Mechanisms: Automatic alarms, emergency discharge, and other safety plans

Seismic and Pressure-Resistant Structure: Stable performance in extreme environments

3. Environmental Performance

Zero Leakage Design: Utilizes leak-proof technologies such as double sealing and special welding.

Environmentally Friendly Materials: Select materials that are recyclable and non-contaminating to the storage medium.

Energy-Saving Features: Thermal insulation reduces energy consumption.

Selection and Usage Recommendations

Media Matching: Select containers with appropriate materials based on the chemical properties of the stored material.

Environmental Adaptability: Consider factors such as the installation environment's temperature, humidity, and seismic intensity.

Life Cycle Assessment: Comprehensively consider initial investment, maintenance costs, and replacement cycles.

English

English  русский

русский  Español

Español