Jiangsu Haijian Co., Ltd is a professional China Cement Roller Press Manufacturers and Cement Roller Press Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

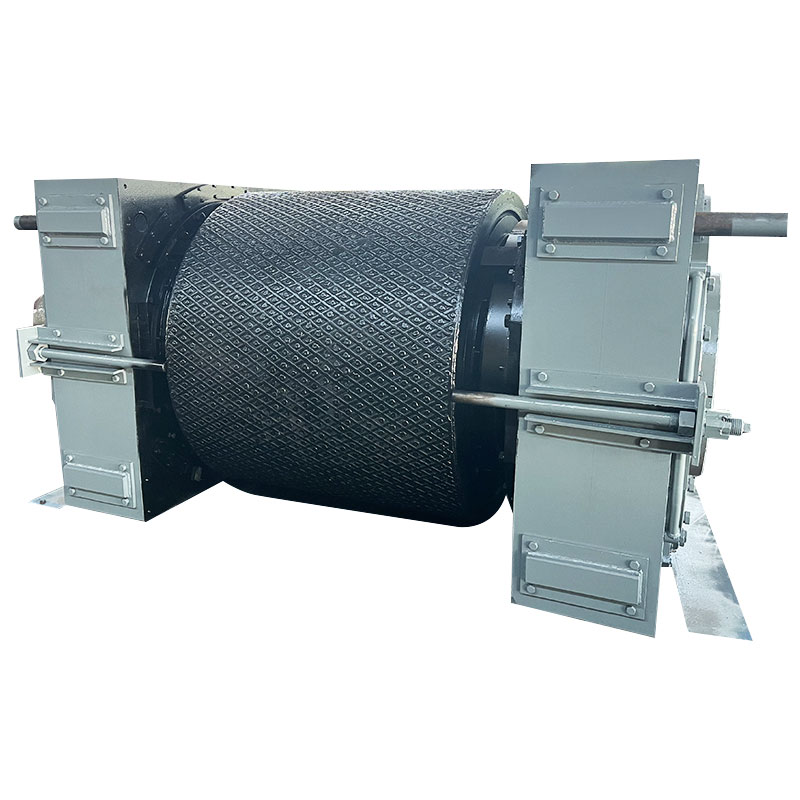

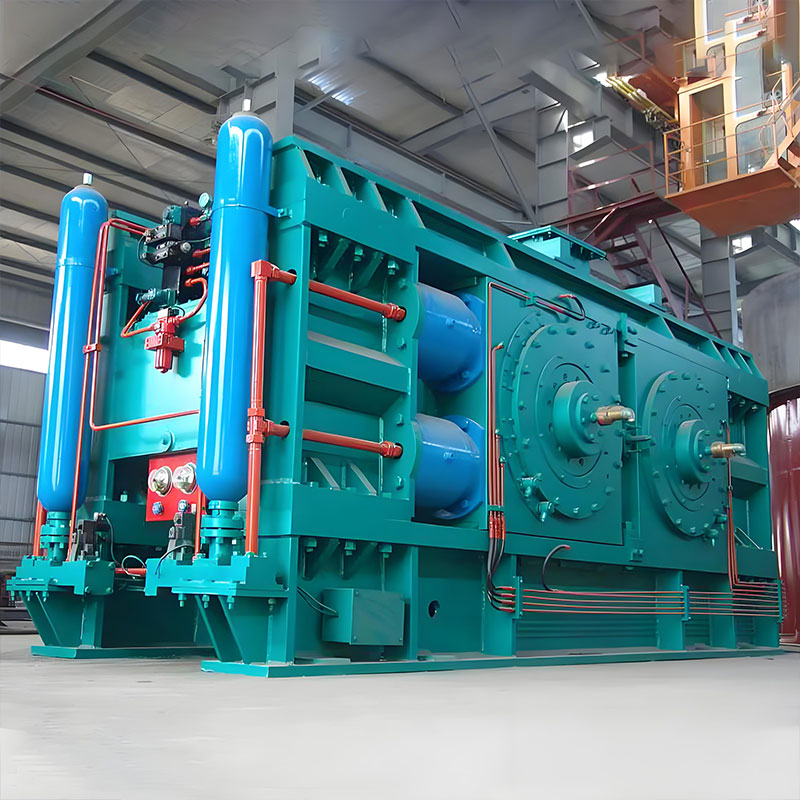

Roller presses are essential industrial equipment, widely used in metallurgy, building materials, mining, and other fields. They are primarily used for plastic processing of metal and non-metallic materials. Their core function is to transform the material's shape and properties through intense pressure, adapting them to the needs of subsequent processing or direct use. Whether rolling steel plates, forming metal bars, or processing ceramics and composite materials, roller presses efficiently complete processing tasks, improving production efficiency and product quality.

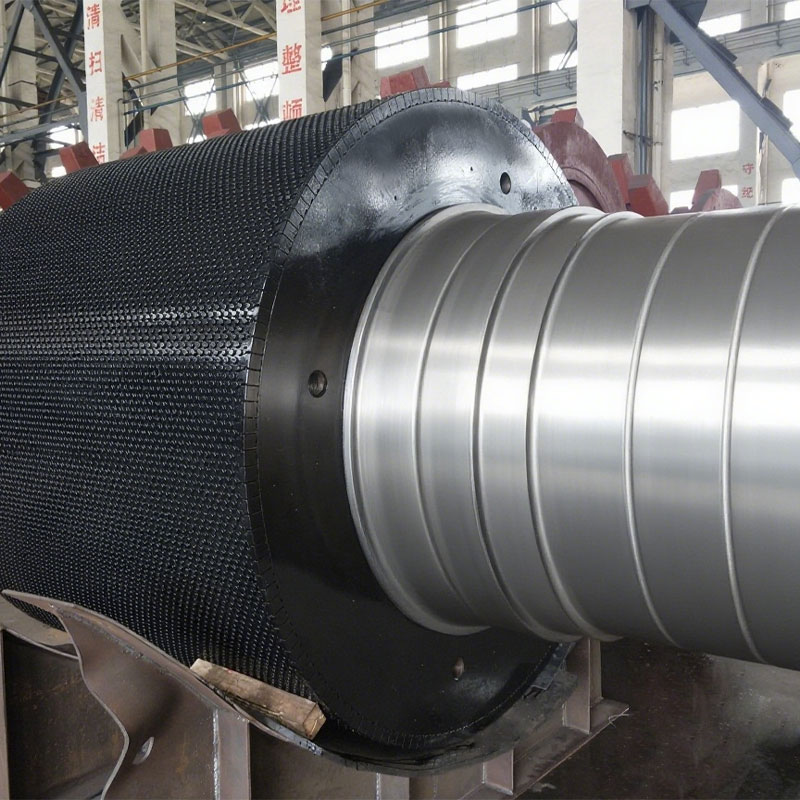

Jiangsu Haijian Co., Ltd. is a professional cement roller press manufacturer and company. We are a major manufacturer, key backbone enterprise, and a major export base for cement, power, environmental protection, and metallurgical mining equipment in China. The operating principle of a roller press is based on the combination of roller rotation and pressure. The equipment typically consists of one or more pairs of parallel rollers. As the material passes between the rollers, it is subjected to compression and friction, resulting in plastic deformation. The roller gap, speed, and pressure applied can be precisely adjusted to suit the material's properties and processing requirements. For example, during the metal rolling process, hot billets undergo multiple roll passes, gradually thinning and elongating them to form the desired sheet or strip. The roller press's control system ensures stability and consistency during the process, thereby guaranteeing product dimensional accuracy and surface quality.

Regarding ongoing maintenance, the stable operation of a roller press relies on regular maintenance and inspection. Because the equipment operates under high pressure and load, key components such as rollers, bearings, and drive systems are susceptible to wear and fatigue, requiring regular lubrication, cleaning, and replacement of wearing parts. Furthermore, the stability of the hydraulic and electrical control systems requires special attention to prevent equipment downtime due to oil contamination or circuit failures. Furthermore, proper operator use and routine inspections are crucial. A sound maintenance strategy not only extends the service life of the roller press but also reduces unexpected failures, ensuring continuous and efficient operation of the production line.

English

English  русский

русский  Español

Español