Jiangsu Haijian Co., Ltd is a professional China Industrial Pressure Vessel Suppliers and Industrial Pressure Vessel Factory. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient syste...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how ex...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized ...Read More -

Admin 2026-01-08

How does a complete cement production line operate?

Cement, as an indispensable material in infrastructure construction, has its quality and output directly affecting project progress and structural safety. The s...Read More -

Admin 2026-01-01

How to Choose the Right Cement Production Line Equipment?

A cement production line is the core equipment for the production of building materials. Its performance and configuration directly affect production efficiency...Read More

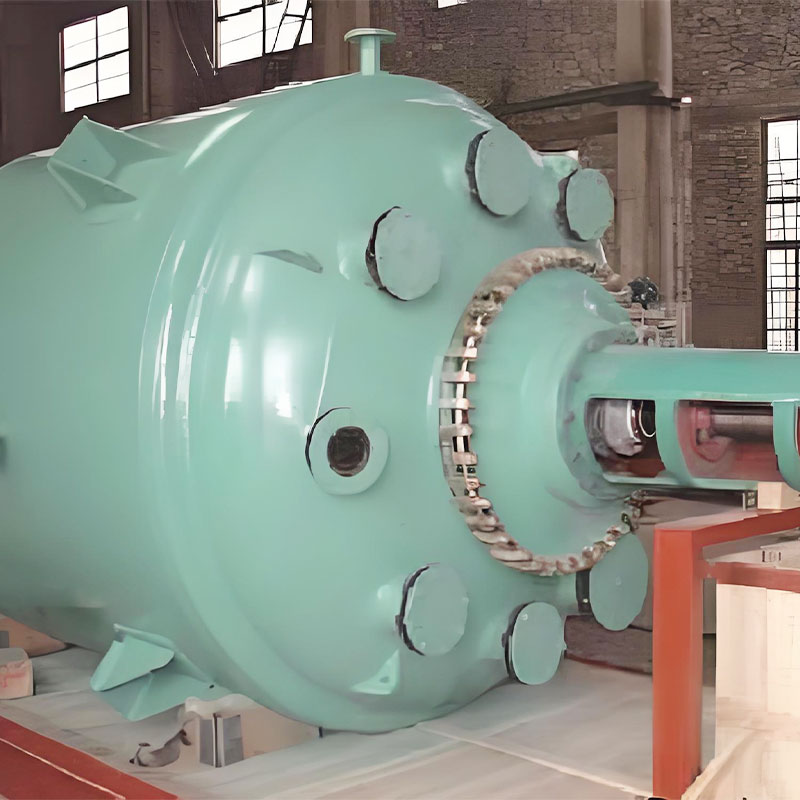

Industrial pressure vessels are key equipment in the industrial system, playing an irreplaceable role in the petrochemical, energy and power, pharmaceutical, and food sectors. These specialized devices withstand internal or external pressure to enable processes such as material storage, reaction, separation, and heat transfer.

Jiangsu Haijian Co., Ltd. provides specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgical applications. Industrial pressure vessels can be categorized by process function into reaction vessels (such as polymerization reactors), heat exchange vessels (such as shell-and-tube heat exchangers), separation vessels (such as vapor-liquid separators), and storage vessels (such as spherical tanks). In terms of structural design, cylindrical and spherical geometries with excellent pressure-bearing properties are commonly used, and advanced design methods such as finite element analysis are used for stress optimization. In terms of material selection, in addition to traditional carbon steel and low-alloy steel, specialty materials such as duplex stainless steel and nickel-based alloys are increasingly being used to meet the demands of specialized operating conditions such as high temperature, high pressure, and severe corrosion.

Industrial pressure vessels require a systematic management system for maintenance:

1. Daily Maintenance:

Regularly check the integrity of safety accessories (safety valves, pressure gauges, etc.)

Monitor equipment operating parameters (pressure, temperature, etc.) for normal operation

Maintain the cleanliness of equipment surfaces and the integrity of the anti-corrosion coating

2. Periodic Inspections:

Perform annual and comprehensive inspections in accordance with standards

Focus on inspecting stress concentration areas such as welds and openings

Evaluate equipment condition using non-destructive testing methods such as ultrasound and radiography

3. Maintenance Management:

Establish comprehensive maintenance records

Major repairs must be performed by qualified personnel

Pressure and airtightness tests must be performed after maintenance

4. Technical Improvement:

Timely update of outdated equipment

Apply new monitoring technologies (such as acoustic emission monitoring)

Optimize operating process parameters

English

English  русский

русский  Español

Español