Jiangsu Haijian Co., Ltd is a professional China Lime rotary kiln Manufacturers and Lime rotary kiln Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

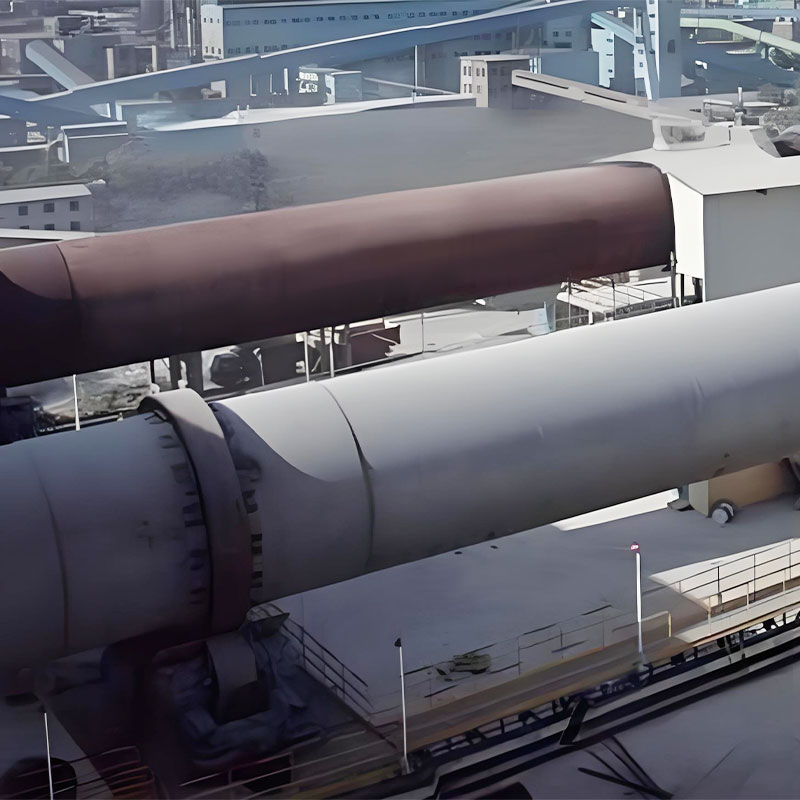

As the core equipment for active lime production, the lime rotary kiln converts limestone (CaCO₃) into highly active calcium oxide (CaO) through high-temperature calcination. It is widely used in industries such as steelmaking, calcium carbide chemicals, environmental desulfurization, and building materials. Its unique thermal design and stable operating performance make it the preferred technical solution for large-scale lime production. In the steel industry, the active lime (activity ≥ 360mL) produced by this equipment can improve steelmaking dephosphorization and desulfurization efficiency, reducing metallurgical auxiliary material consumption by 15%-20%. In the environmental protection sector, the calcined high-purity calcium oxide (CaO ≥ 92%) is a key reagent for flue gas desulfurization. In chemical production, the precisely controlled calcination process produces lime products with varying activity levels, meeting the needs of niche industries such as calcium carbide and bleaching powder. The rotary kiln's adaptability to multiple raw materials enables it to process limestone with particle sizes ranging from 5 to 40mm and even incorporate 10%-15% of industrial waste slag (such as steel slag and calcium carbide slag), achieving efficient resource utilization.

Jiangsu Haijian Co., Ltd. is a professional lime rotary kiln manufacturer and company. We provide specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgy applications, widely used in the industrial sector. The operating principle of the lime rotary kiln is based on the synergistic effect of high-temperature pyrolysis and dynamic calcination. A steel cylinder tilted 3%-4% rotates at a speed of 0.5-4 rpm. Limestone is fed into the kiln at the rear and, driven by the kiln's rotation and internal material handling, undergoes four process stages: preheating, decomposition, calcination, and cooling. The core calcination zone maintains a temperature between 1050-1250°C, utilizing multi-channel burners (compatible with various fuels, including pulverized coal, gas, and biomass) to precisely control the temperature gradient (±10°C).

The lime rotary kiln's intelligent maintenance system integrates modern monitoring technology with preventive maintenance strategies. Refractory management utilizes 3D laser scanning technology to generate a kiln lining thickness cloud map (accuracy ±2mm). Automatically alert when the remaining thickness of refractory bricks in the fired zone is less than 100mm. The supporting roller bearings are equipped with a dual-parameter vibration and temperature monitoring module, which uses an algorithm to analyze wear trends (with an early warning accuracy rate of ≥90%). The gear transmission system implements online oil monitoring, and the filter element replacement procedure is triggered when the ferrography analysis shows wear particles greater than 20μm.

English

English  русский

русский  Español

Español