Jiangsu Haijian Co., Ltd is a professional China Drying machine Manufacturers and Drying machine Company. We provide professional cement production equipment, industrial solid waste incineration equipment, and professional equipment for mining and metallurgical applications.We are a major manufacturing enterprise, a key backbone enterprise, and a primary export base for cement, power, environmental protection, and metallurgical and mining equipment in China. The company has the legal rights to independently manage the import and export of its products and is legally authorized to undertake general contracting for foreign projects.

-

Professionalism

-

Quality

-

One stop solution

News Center

News Updates

-

Admin 2026-01-30

Cement Production Line: Is It the Most Efficient Way to Build Modern Infrastructure?

A cement production line is the backbone of large-scale construction projects and urban development. By integrating automated processing, energy-efficient systems, and quality control technologies, modern cement production lines deliver consistent output and stable material performance for global in...Read More -

Admin 2026-01-22

What is a Cement Production Line and How Does It Work?

Cement production is the backbone of the construction industry, providing the essential material used in building everything from houses to highways. But how exactly is cement made, and what role does a cement production line play in this process? In this article, we’ll explore what a cement product...Read More -

Admin 2026-01-16

Is cement production line equipment maintenance difficult?

Many cement plant managers ask: Is cement production line equipment maintenance very complicated? Will it delay production? Actually, as long as a standardized maintenance process is established, daily maintenance is not difficult and can effectively reduce downtime and extend equipment lifespan. Re...Read More

Industry knowledge

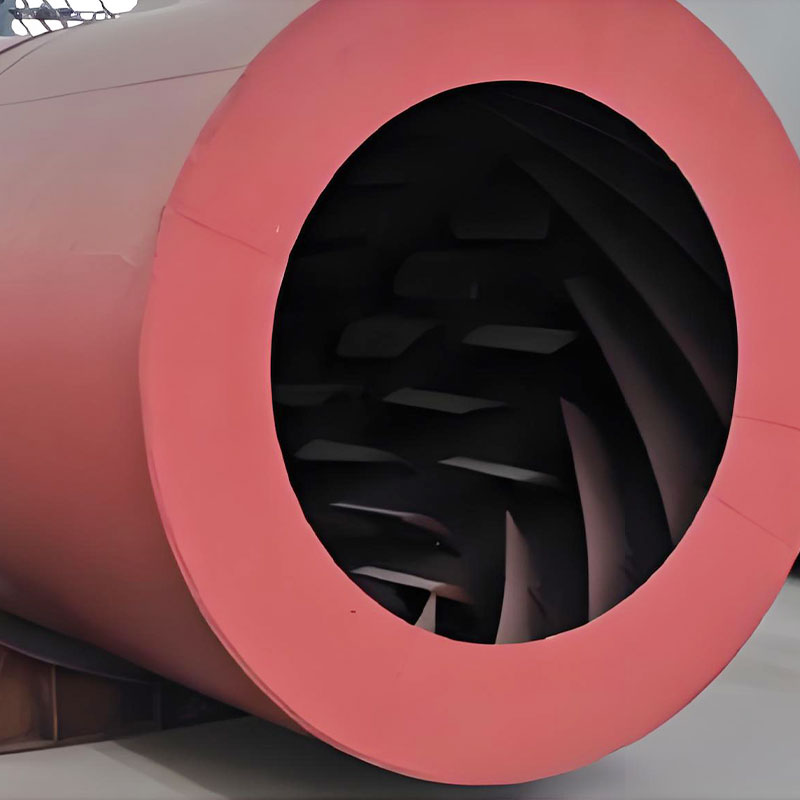

In the building materials and metallurgical industries, drying machines are key equipment for material pretreatment, responsible for drying raw materials such as slag, clay, pulverized coal, and leached residue. Jiangsu Haijian Co., Ltd. is a professional drying equipment manufacturer and company, providing specialized equipment for cement production, industrial solid waste incineration, and mining and metallurgical applications. The company holds independent import and export rights and general contracting rights for foreign projects. Through its innovative structural design and optimized thermal system, the drying machine achieves breakthroughs in both energy consumption and production efficiency, providing the industry with a more economical and environmentally friendly drying solution.

The dryer integrates multiple lifting devices, combining flow diversion, flow distribution, and lifting functions. Its unique curved structure and arrangement create a thin, evenly distributed curtain across the radial cross-section of the drum. This design ensures that material particles are fully exposed to the hot airflow, increasing the heat exchange area by over 40% compared to traditional dryers. Combined with an optimized drum speed (typically controlled at 3-8 rpm) and inclination angle (3-5°), the material residence time within the drum is precisely controlled, ensuring maximum water evaporation efficiency.

The hot air system utilizes a countercurrent heat exchange principle. High-temperature flue gas (600-800°C) is introduced at the feed end, moving in the opposite direction of the material. The innovative air duct design ensures more uniform hot air distribution, maintaining a stable velocity within the optimized range of 1.5-2.5 m/s. This ensures efficient heat transfer while preventing fine particles from being carried away by the airflow. A high-efficiency cyclone dust collector is installed at the tail end, keeping the dust content in the exhaust gas below 50 mg/m³, meeting environmental emission requirements.

Daily maintenance focuses on the following:

Weekly check the lift plate for wear and replace any deformed parts promptly.

Monthly clean the dust removal system and inspect the seals.

Quarterly calibrate temperature and pressure instruments.

Inspect the cylinder for straightness and roundness during the annual overhaul.

English

English  русский

русский  Español

Español